Tubes & profiles cutting

Programming of tubes and profiles cutting machines using the Almacam Tube software

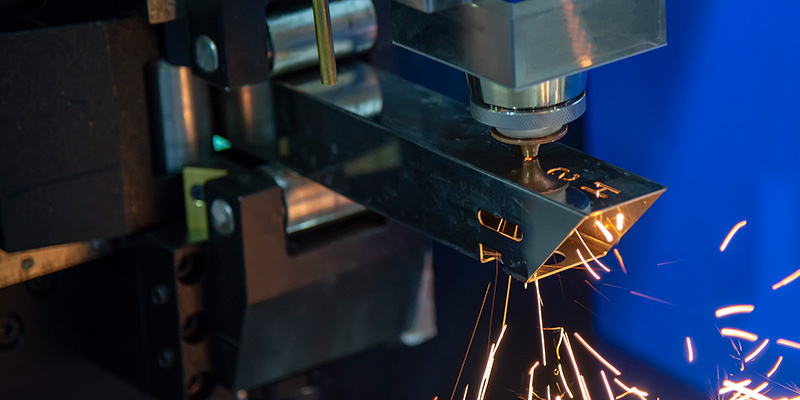

Alma has always supported development of tube cutting technology, and the associated innovations. Today it is possible to automatically control increasingly complex machines to cut tubes with standard or special sections, as well as all types of profiles. The Almacam Tube software meets the specific needs of laser cutting, plasma cutting and oxy-cutting.

Tubes and profiles-cutting processes

Technological breakthroughs over the last few years now make it possible to build highly automated, flexible tube cutting machines and robots, using increasingly sophisticated mechanisms: complex kinematics with multiple rotative axes, loading/unloading units, coupling and clamping systems, sensing units, etc. Other complex machines combine laser technology with mechanical operations such as conventional drilling, friction drilling, threading, countersinking or counterboring.

Different technologies such as laser, plasma and oxy-cutting are used to cut tubes and profiles with varied dimensions, geometries and thicknesses. Laser cutting combines speed, precision (+/- 0.2 mm) and burr-free cutting quality up to a thickness of approximately 20 mm, whereas plasma and oxy-cutting make it possible to cut thicker tubes at a lower cost.

The application fields for cutting tubes and sections are extremely varied: metal furniture, automobile industry, agricultural machinery, various consumer goods, and of course metal structural frameworks.

A specialized CAD/CAM software for tubes and sections facilitates design and preparation of parts and assemblies, whether this is for prototypes or mass production.

Advantages and benefits of Almacam Tube for cutting tubes and profiles

Given the investments required to install a system for cutting tubes and profiles, it makes no sense to penalize productivity with a programming software that is unsuitable or insufficiently automated. When you opt for the Almacam Tube CAD/CAM software, which has already been installed on many machines and is capable of managing several cutting technologies, you are choosing an automated, effective and open-ended solution.

Almacam Tube enables you to model and control all systems for cutting tubes and profiles, and their equipment:

- Machines with multiple axis heads

- Machines with several rotative axes

- Automated loading and unloading systems

- Coupling and clamping systems

- Sensing systems

- Robotized cells for cutting tubes and sections

- Management of any kinematics specific to the machine

Almacam Tube supports all the steps in the process for cutting tubes and profiles:

- Importing and CAD/CAM modifications of single parts and assemblies

- Modeling of tubes and profiles

- Automatic nesting of tubes or sections to cut, with possibility of common cutting

- Automatic creation and scheduling of cutting trajectories, supporting the constraints and specificities of each technology (laser, plasma, oxy-cutting)

- Automatic generation of the cutting program. Support for tube coupling and clamping rules.

- Automated management of systems for loading and unloading tubes and off-cuts.

- Generation of the NC files specific to the machine or robot.