Contact us

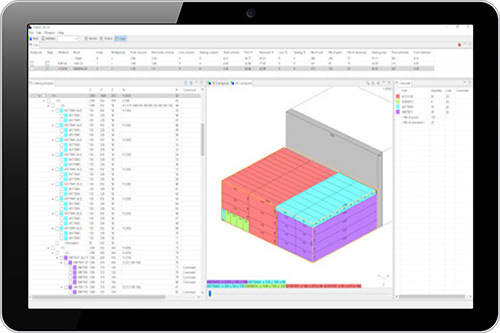

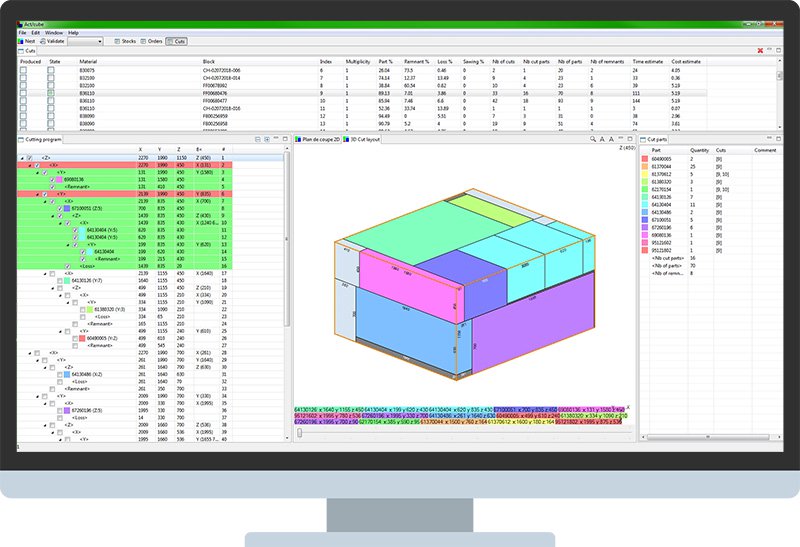

Almacube, a 3D nesting software for volume cutting

The software for nesting parallepipedic blocks to cut foam, stone, wood, etc.

Almacube is a 3D nesting software for professionals cutting materials such as foam, polystyrene, steel, marble, wood, etc. From a set of raw-material blocks and a set of outputs to be produced, Almacube automatically calculates the 3D layout using a powerful optimization algorithm. This results in an optimized use of material, and therefore, significant material and time savings.

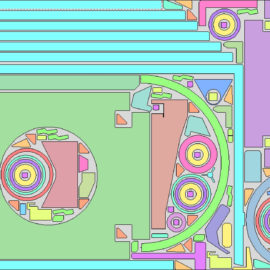

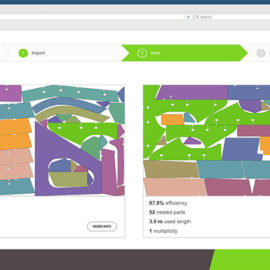

Possible applications