Almacam WAAM: CAM solution for robotized Additive Manufacturing

A solution for robotized additive manufacturing using weld bead deposition processes, designed in partnership with ESPRIT.

The Wire and Arc Additive Manufacturing (WAAM) technology is installed on a robotized cell. It is used to create 3D parts by means of successive welding bead deposits. This technology makes it possible to very quickly manufacture large metal parts at reduced cost, opening up new horizons for additive manufacturing.

Based on this observation and their respective CAD/CAM expertise in programming machining operations and off-line programming of robots, DP Technology (ESPRIT) and Alma partnered to design a single Additive Manufacturing solution dedicated to robotized DED-WAAM processes.

This CAM solution combines the ESPRIT and Almacam Weld software, to manage the entire robot programming process. The ESPRIT CAM can then be used to finish the part by removing material.

Advantages and benefits of WAAM technology

Additive manufacturing technologies are undergoing rapid development in industry. They allow for greater freedom in the conception and design of parts than subtractive manufacturing technologies that operate by removing material. In some cases they also consume less energy and generate less waste.

WAAM technology also has several advantages over metal additive manufacturing processes that use powder beds: rapidity producing rough-machined parts, better control of the supply chain, reduced production costs due to the smaller investment represented by a robotized cell, even when including the need to rework the rough-machined parts to correct their poor surface condition.

WAAM technology also meets hybrid requirements, by combining with 5-axis machining or robotized milling. It also opens up promising possibilities on the market for repair or manufacture of large parts, in particular in the aeronautics and automobile industries.

A comprehensive robot programming solution

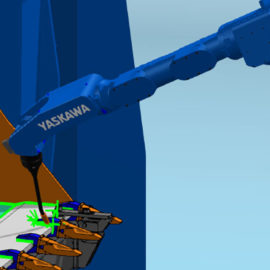

The Almacam WAAM solution manages the entire process for programming a 6-axis welding robot, whether or not it is equipped with a manipulator:

ESPRIT CAM can then be used to finish the part by removing material (substractive).

The Almacam WAAM solution has been validated on YASKAWA robotized cells and can be adapted to any type of 6-axis welding robot.