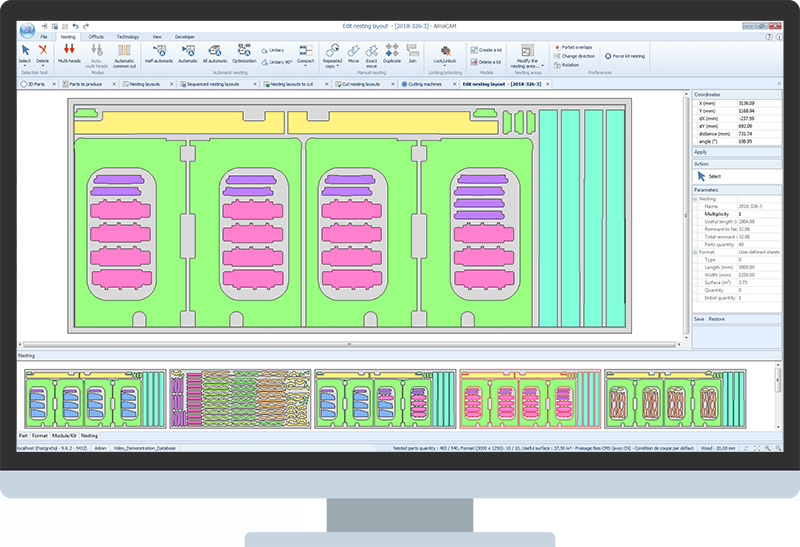

Almacam Routing, a CAD/CAM software for routing of soft materials

The nesting software for routing and 2.5 axis machining of aluminum sheets and wood panels.

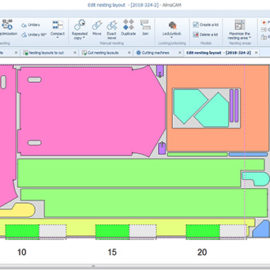

Alma has acquired specific expertise in developing software for routing and 2.5 axis machining of wood, aluminum and soft materials. The Almacam Routing CAD/CAM software is a high added value specific solution for industrial companies who have substantial parts nesting needs and therefore work in small and medium series.

Testimonial

“The Beneteau Group chose Alma as early as 1990 to optimize the cutting of the wood parts used for the partitions and inside arrangements of boats. In order to homogenize our production means, today we use act/cut to program the routing machines of 4 production sites in France and the United-States. The software manages a great diversity of machines and processes: one-sided or double-sided routing of nested parts, edge machining and specific operations on single parts, routing one panel after the other or routing of stacked panels, machining on both sides of the panel… In 2009 the introduction of the module that enables us to directly and automatically assign machining to 3D CAD parts has significantly simplified the preparation and assignment of the parts to the machines.”

Benoit Mériau – Industrial IT Director, Beneteau Group

The perfect software for routing every kind of material.

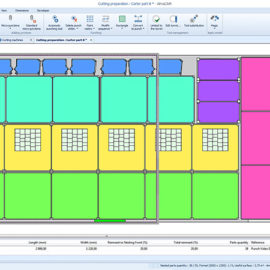

2.5 axis machining of wood panels

Almacam Routing is used in particular for interior design work in yachts, caravans, recreational vehicles, kitchens, offices, etc.

Almacam Routing manages routing of “top side” and down side” parts followed by machining if necessary (“top side”, “down side” and on edges) for individual parts.

Thanks to a specific wood module which combines geometry recognition and automatic machining functions, Almacam Routing enables you to import and automatically prepare any CAD-designed 3D part.

Routing of aluminum sheets

For more than 25 years, Alma has specialized in this technology specific to the aeronautics industry. With high nesting performance and the ability to meet all the technological requirements and constraints of the routing process (multi-layer machining, screwing, riveting, micro-junctions, etc.) Almacam Routing is the ideal system to program your aluminum routing machines.