Experience a true CAD/CAM partner

Almacam, the unified CAD-CAM software for Nesting, Cutting and Robotics

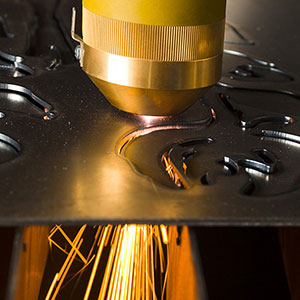

Across the world, manufacturers rely on our CAD/CAM and automatic powerful nesting software to make their cutting, sheet metal, and welding systems more efficient and Industry 4.0-ready

Alma, the Nesting Company

For 45 years, Alma is the only player on the market to develop in-house nesting algorithms and deliver them in different formats: as software components for CAM or ERP providers, and as ready-to-use CAM software for industrial subcontractors. Proof that our algorithms are the most efficient!

The right solution for every customer

Sheet Metal Manufacturers

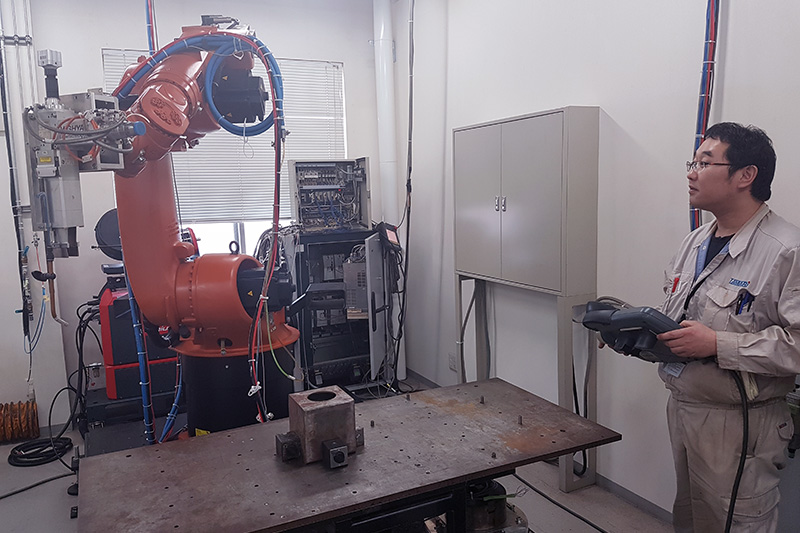

Our CAD/CAM software products control all the technological processes for sheet metal working and machine welding, from standard machines to the most complex installations that exist. They adapt to every production configuration and integrate into all the information systems. They deliver immediate measurable gains and are designed with the user’s comfort in mind.

Machine Tool Builders

Our software products can be customized and easily integrated by a manufacturer or an integrator. Combined with the technical performance of the Alma software, this advantage gives the manufacturer’s solution decisive added value. Alma offers the manufacturer a bespoke partnership and a broad portfolio of services, right around the world.

Software Companies

Alma is the only Cutting CAD/CAM vendor that in parallel with its software applications commercializes its nesting algorithms in the form of software components. These are designed to integrate into applications developed by third parties: CAD/CAM or ERP software developers, manufacturers commercializing their own software, etc.

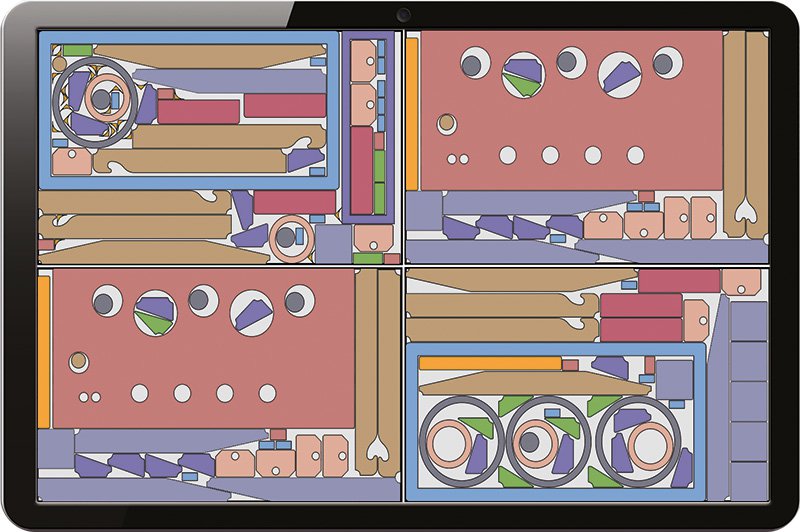

Product focus: quotation for sheet-metal

A new version of Almaquote, the quotation software for sheet metal and mechanical welding, is available. An even more intuitive user interface and new features to make quotations even faster and more accurate, whether you are a subcontractor or a manufacturer!

- Quote information visible at a glance.

- Management of multi-level BOMs with the associated operations.

- Possibility to reuse existing BOMs in the future.

- Graphics tools to analyze key information relating to quotes.

- Access to the Webquote online service allowing to manage requests for quotes.

- Direct connection to the Assembly2cam CAD assembly importing module.

Discover this new version in video.

Alma in 0110110

8 000

clients

20

countries

43

years of experience in CAD/CAM

175

crew members